METEL B.V. is a unique supplier and specialist in high-performance metals.

the following materials are available at metel B.V.

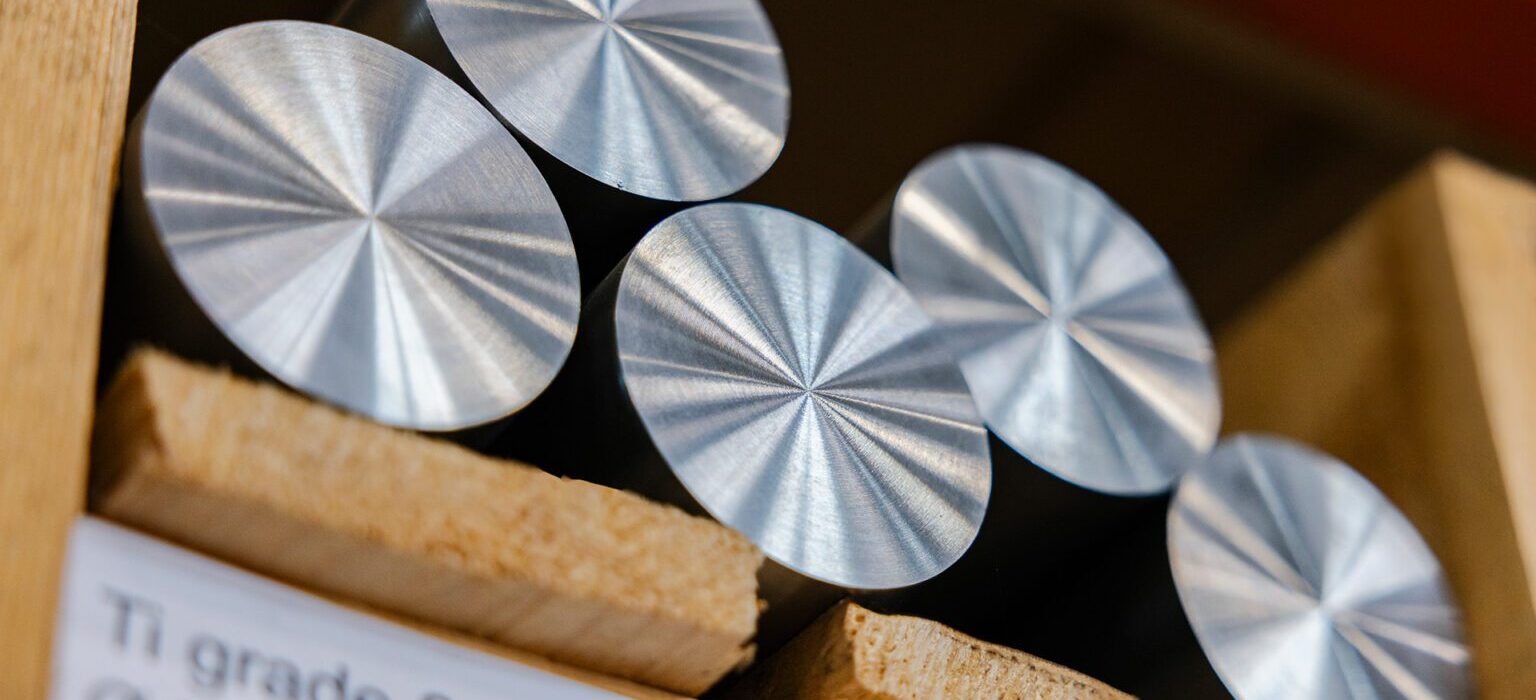

Machined parts

Partners

Are you looking for hard to find metals?

Are you looking for hard to find metals? Then you’ve found the right source with Metel, a specialist in the supply of high-performance and special metals. Metel is not focused on the high-volume market and mass production, but instead on its customers’ needs. What makes high-performance metals special? Their specific properties, such as superior thermal resistance, high electrical conductivity, high corrosion resistance, and a specific tensile strength. This is what makes these metals able to perform well in extreme environments.

With in-depth knowledge and a no-nonsense mentality, we will be happy to recommend the best metal for your problem. Are you looking for an alloy with unusual dimensions and specific tolerances? Need a special metal? In addition to semi-finished products, we also supply completely machined parts according to the drawings and specs you supply. Just send us a technical drawing and we’ll do the rest.