Molybdenum is a hard and lustrous, silvery metal with a high melting point of 2623°C. That is why pure molybdenum is often used in applications that involve prolonged and high temperatures.

Download our Molybdenum datasheet here

Datasheet download

Vul het formulier in en ontvang uw brochure per mail.

- Good strength and mechanical stability for high temperature applications

- Excellent chemical resistance

- Molybdenum alloys can be very wear-resistant

- High-temperature heating elements

- Rocket engines

- Welding electrodes

- Glass production equipment

- Missile technology

- Smooth coatings

The distribution of the produced molybdenum

About 80% of the produced molybdenum is used as an additive to steel and cast iron. The addition of molybdenum strongly increases the strength of steel, making it more corrosion-resistant and more resistant to fluctuating temperatures than normal steel. The remaining 20% is used for chemicals, pure-molybdenum metals, and alloys.

The oxidation and sublimation of molybdenum

Molybdenum starts to show signs of oxidation with temperatures of more than 500°C when it gets into contact with oxygen. Sublimation, the transition of solid molybdenum into a gas state, starts from 600°C. Within a vacuum environment, molybdenum can withstand prolonged temperatures of 1200°C without losing hardly any of its strength.

Material limitations of molybdenum

The most important limitations to using molybdenum are recrystallization and temperature. Heating of molybdenum and its alloys above their recrystallization temperature makes them brittle, causing the material to tear due to changes in the grain structure. The recrystallization temperature can be increased by, for instance, dipping molybdenum in lanthanum oxide. This improves its ductility and increases the recrystallization temperature.

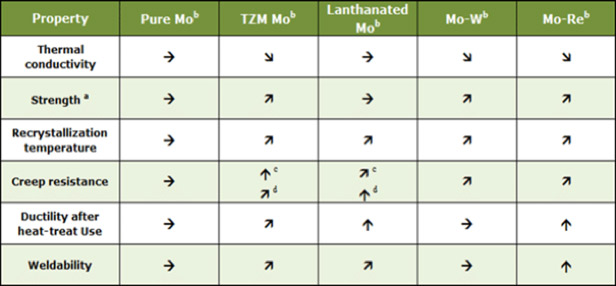

In the image, you can find the most important material properties per molybdenum alloy:

The use of molybdenum in ovens

Molybdenum is heat resistant to about 1900°C. Are you looking for a metal that can handle such high temperatures? Then tungsten will be the best option. Materials that can withstand temperatures from 1315°C and higher are often used for the production of industrial vacuum ovens. Of all refractory metals, molybdenum is most commonly used as it is the most cost-effective choice.

Molybdenum alloys

The most used molybdenum alloys, by far, are pure molybdenum, molybdenum/lanthanum (MLR), and molybdenum TZM (titanium zirconium molybdenum).

Elementary additions for the best material properties

The mechanical properties of molybdenum are determined by its purity, elements added, and the microstructure. Properties such as strength, ductility, temperature-resistance, and processibility are improved by the addition of elements such as titanium, zirconium, hafnium, carbon, and potassium and/or together with oxides of lanthanum, yttrium, and caesium.

Please contact us

You can contact us daily by e-mail and telephone between 8.30 am and 5.00 pm, you can email us 24/7.

Christiaan Huygensweg 2B 5151 DN Drunen

+31 (0) 416 724 800 info@metel.nl