Application of Tungsten in high-tech markets

Tungsten is almost considered a science-fiction metal. Because of its unique properties, it is used in pioneering applications in high-tech industries. But why is a high density or high melting point so important? In this article, we discuss the different reasons tungsten is used in demanding markets and how it works in practice. Tungsten is not always easy to process. Metel offers advice and can even take on the process of manufacturing of tungsten parts.

Tungsten is the name of the chemical element with symbol W and atomic number 74. In English, the element is called “Tungsten” because of a Swedish chemist who made a new foam of tung stones which means “heavy stone”. The foam (Rahm) was combined with Wolf in German because the foam, as it were, ate away at the Tin in the process. This is where the mineral tungstenite got its name from. It was two Spaniards who were the first to successfully isolate tungsten by reducing the acidity with charcoal, they named it Tungsten.

Tungsten rings for two different high-tech applications

Tungsten applications and markets

Tungsten has two very striking properties: it has the highest melting and boiling point of all metals (resp. 3,410 ˚C and 5,930 ˚C) and a density similar to Uranium and Gold, 1.7 times that of Lead. As a result, there are a large number of applications for this high-performance metal, the most appealing is perhaps the filament of a light bulb. Of course, it is the high melting point that makes tungsten so compatible. But there are other interesting applications:

Tungsten as counterweight – Metel supplies tungsten to a customer, for example, who manufactures machines for the separation of plasma, where tungsten serves as counterweight. The same applies to the application of tungsten to the crankshaft of a car.

Tungsten makes more compact construction possible – Engineers can build more compact systems, simply because the specific weight is higher. In the aforementioned plasma separation application, this ensures that the counterweight takes up less space and can therefore be made more compact.

Tungsten blocking radiation – Due to its high density, tungsten is excellently suited for the separation of X-rays and is used, for example, in what used to be called a lead apron.

Tungsten is non-toxic – Unlike lead, tungsten is non-toxic and can therefore be used in many more applications.

Tungsten is highly heat-resistant in a vacuum – The coefficient of expansion of tungsten is low (4.5) compared to lead (29.3), so tungsten is very dimensionally stable and practically indestructible. This is why it is widely used in vacuum oven, for example. This makes tungsten an essential material for the manufacture of high-tech components in the aerospace, semiconductor and energy industries, for example.

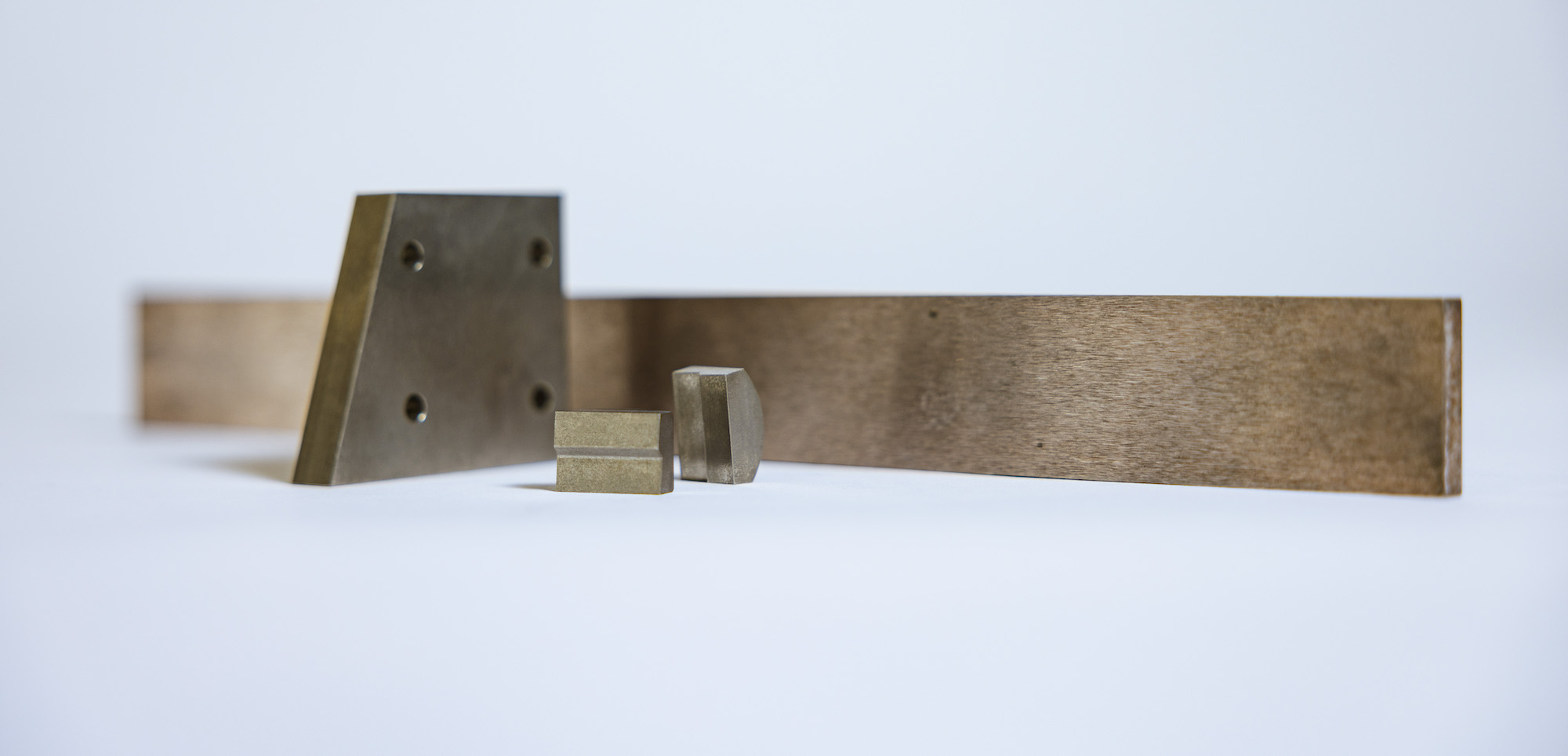

Machined parts from pure tungsten

Processing pure Tungsten (min. 99.95% pure) can be challenging and requires special tooling. It therefore regularly occurs that Metel, in addition to other metals and alloys, supplies its customers with processed tungsten parts. “Our factory has all the knowledge and equipment needed to process the various alloys. An additional advantage is that any loss, for example during machining, is immediately reused. This results in lower material costs.”

Tungsten in various forms

The image above shows copper-coloured tungsten (WCu80). This is one of the important alloys that Metel supplies to its customers. We would like to explain three alloys individually:

Tungsten Copper

In the case of tungsten-copper alloys, the most important consideration is the balance between wear resistance and thermal or electrical conduction. Metel supplies, for example, tungsten-copper in a 70/30 ratio for the manufacture of high-voltage conductors. We determine the right composition in close consultation with the customer.

Tungsten Silver

This alloy is an exceptionally good conductor, better than Copper and even better than Gold. Tungsten Silver is therefore used, for example, in welding electrodes. But the use in ‘open’ air also has disadvantages, because Silver is very susceptible to oxidation. Oxidation will cause the conductivity of the Tungsten Silver to deteriorate relatively rapidly in an application. Therefore, this alloy is mainly used when oxygen does not play a role. In audio cables, for example, tungsten silver is used in combination with a good sheath, which prevents the alloy from being exposed to the air.

Tungsten-Nickel-Copper or Tungsten-Nickel-Iron Alloys

An alloy that offers the advantages of tungsten, but is not as challenging to process as pure tungsten, is for example the W95 or W97 alloy. The number refers to the percentage of tungsten in which the remaining 3 percent consists of nickel in combination with iron or copper. The choice is then determined, for example, by the preferences in terms of conduction and the importance of a high specific weight. The W97 alloy has a specific weight of 18.5 g/cm3, the W95 alloy 17.6 g/cm3. In both cases, the alloy can be processed well.

Alloys

Frequently requested tungsten alloys:

- W90NiFe/W90NiCu

- 5NiFe/W92.5NiCu

- W95NiFe/W95NiCu

- W97NiFe

- W90NiFeMo

Practical example of the application of tungsten

The picture below shows two rings, the left ring has been applied

One of our customers works with the tungsten ring in their breeding/cultivation application shown above (left). These rings are part of a carrier for copper parts that are silver coated in a chemical bath. Since there is current on the chemical bath the parts go through, it is important that the rings are somewhat conductive and corrosion-resistant. A tungsten-copper alloy is the best choice for this.

The left ring is made of the W90 alloy and was found to be subject to too much wear. To reduce the wear of these parts, we looked at the various tungsten alloys together with this customer. Pure tungsten turned out to be too expensive and the W97 alloy was a step in the right direction. Ultimately, the W95NiCule alloy (3.5% nickel, 1.5% copper) was chosen as the most cost-effective solution.

The thicker ring is applied in a high-tech electron microscope to beam electrons in a straight beam.

Curious about the benefits of working with Metel? Our team will be happy to tell you all about our programme or our approach and will be glad to share examples of successful partnerships with customers who operate in your specific market. Make an appointment by calling 0416 – 724 800 or send an email to n.kesteloo@metel.nl.