Invar 36: the remarkable alloy with near-zero thermal expansion

Containing 36% Nickel, Invar 36 is a unique alloy that is applied in markets ranging from scientific instruments to industrial machine building. Why is Invar 36 so remarkable and is it readily available? These are the questions we discuss in this in-depth article on the Nickel-Iron Alloy that is also known as FeNi36. Of course, we also talk about the machinability of it, one of the key concerns for many of Metel’s clients.

Metel is pleased to offer direct-from-stock availability of Invar 36, ensuring immediate delivery for our clients. Our inventory primarily consists of round bar stock, catering to immediate needs with efficiency and reliability. Additionally, we offer a wide range of other forms, including sheet, square bar, tubing, and more, all of which can be supplied directly from the Nickel factory. This comprehensive approach allows us to meet diverse requirements, providing customized solutions while maintaining the high-quality standards our clients expect.

“Machinability is a primary concern for our clients when selecting Invar 36,” states Nick Kesteloo, manager at Metel. “We’ve had clients switch to us, astounded by the superior milling experience with our Invar 36. The forging and annealing process we employ yields a more uniform metal, significantly enhancing its machinability. This ensures the Alloy’s quality is not just about its inherent properties, but also about how it’s processed to meet high machining standards.”

About Invar 36

Invar 36 stands out as a remarkable Alloy with unique properties that made it indispensable for various high-tech industries. Discovered in the early 20th century by Swiss physicist Charles Édouard Guillaume, earning him the Nobel Prize in Physics, the Nickel-Iron Alloy – also known as FeNi36 – is remarkable because of its exceptionally low coefficient of thermal expansion. This characteristic, virtually unmatched by any other Metal or Alloy over a range of temperatures, has cemented Invar 36’s role in applications where dimensional stability is critical. Applications range from intricate scientific instruments to large-scale industrial machinery. Its discovery not only marked a significant milestone in Alloy development but also opened up new avenues for technological advancements, highlighting the alloy’s enduring significance in the ever-evolving field of specialty Metals.

Invar effect

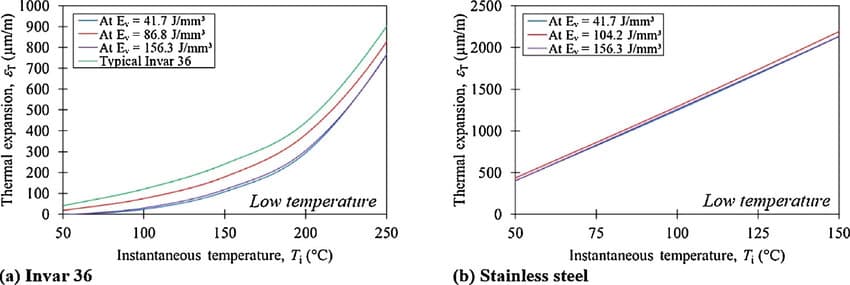

The name Invar 36 comes from the composition of the Alloy, 36% Nickel and 64% Iron, which results in a near-zero expansion due to temperature fluctuations. Up to a certain point, of course, when the temperature exceeds 200°C the expansion rate starts to increase, even though it is still lower than many common Metals. This phenomenon was named the ‘Invar effect’ because Invar 36 is the most notable example of this property. The Invar effect is the primary reason for selecting Invar 36 as a material for your components and is often used in:

- Scientific instruments

- Aerospace

- Telecommunications

- Transport of liquid gasses

- Industrial machine building

Unique combination: Invar 36 and glass

A typical application of Invar 36 in combination with glass is in the manufacturing of precision optical instruments, such as telescopes, microscopes, and laser systems. In these applications, Invar 36 is used to create critical Metal-to-glass seals and components that require exceptional dimensional stability across a range of temperatures. The use of Invar 36 in such applications allows for the creation of optical systems with superior stability and precision, enabling accurate observations and measurements that are critical in scientific research, navigation, and in various fields of engineering and technology.

Availability and cost

At Metel, Invar 36 is readily available. We hold a significant stock of the alloy in our own warehouse and can ship at short notice. In terms of prices, these of course fluctuate, but at the moment Invar 36’ price per kilo is roughly the same as Titanium Grade 5. This makes the Alloy relatively economical when you consider its extraordinary properties.

Every batch is accompanied by the original factory certificate, the 3.1 certificate, with the batch’s mechanical properties and chemical analysis. This helps us, and our clients, guard the consistency of the Metal and its impact on machinability.

Would you like to know more about our specialty Metals and the services we provide? Please contact us via 0416 – 724 800 or mail n.kesteloo@metel.nl.