Zirconium is highly heat and corrosion resistant

Did you know that Zirconium plays a crucial role in both enabling and stopping a nuclear reaction in a nuclear power plant? Before explaining this, we first outline the key properties of Zirconium, compare it to Titanium, and list some different applications.

What is Zirconium?

Zirconium is a transition metal derived from the mineral Zircon, its atomic number is 40, and we characterize this element with the symbol Zr. Zirconium was discovered as early as 1789 but was only isolated in pure form in 1914.

The chemical element Zirconium is one of the most common elements in the Earth’s crust, yet Zirconium is not extracted from the ground in it’s pure form. The mineral zircon, from which Zirconium is isolated, is often obtained as a byproduct of mining Titanium and Tin. In the process of converting Zircon to metallic Zirconium, a small amount of Hafnium is also produced. Zircon is found primarily in Australia, America, South Africa, Brazil, India, and Russia.

Properties of Zirconium

The silver-gray transition metal Zirconium is very versatile. Some characteristic properties are:

- Corrosion-resistant

- High degree of bio-compatibility

- Ductile and malleable

- Very strong, even at high temperatures

- Transparent to neutrons

Zirconium compared to Titanium

Zirconium and Titanium exhibit some similar properties, perhaps not surprising considering that we often extract Zirconium as a byproduct of Titanium. But what are the similarities and differences?

Similarities

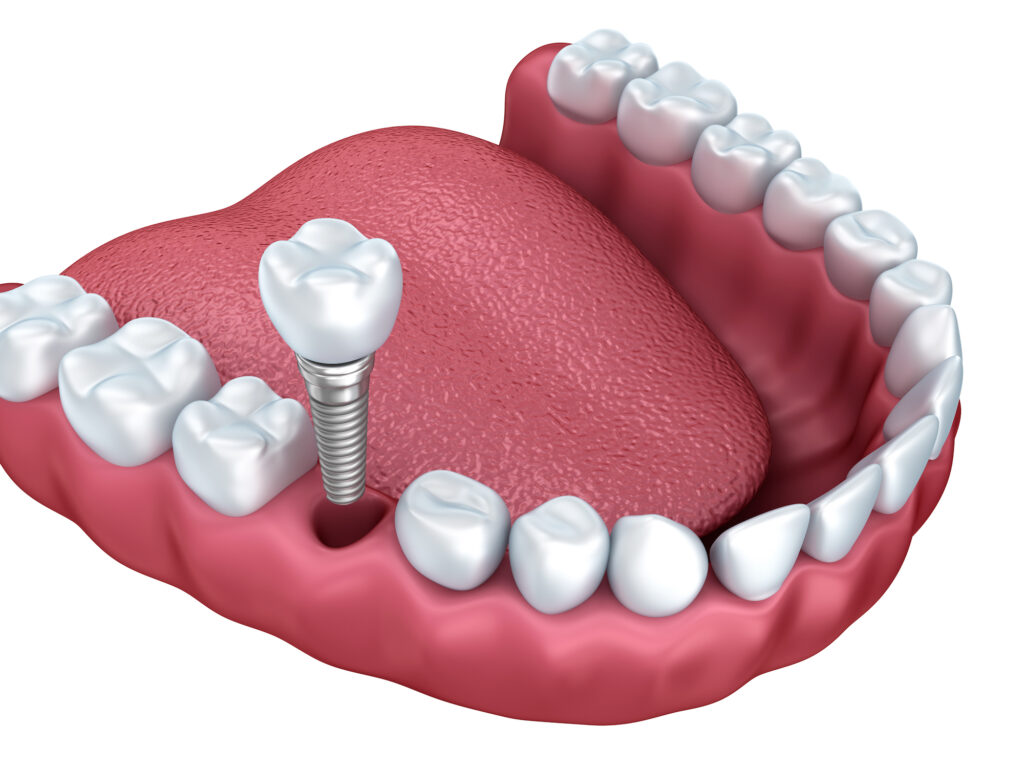

Both metals have a high melting point and are very resistant to corrosion due to their strong, stable oxide layer. When we compare pure Zirconium to pure Titanium, is Zirconium the strongest of the two. Especially at high temperatures and in strong chemical substances, Zirconium’s corrosion resistance is better. However, there are Titanium alloys (such as grade 5) that are many times stronger than all Zirconium variants. Both, Titanium and Zirconium are very strong, relatively light and have a good weldability . In addition, both metals are non-toxic and biocompatible with the human body, making them suitable for medical applications, such as dental technology and surgical instruments.

Differences

The metals differ mainly in application, and investment. Titanium and Zirconium are used for different applications in different markets, Zirconium is widely used in nuclear energy and highly chemical processes while Zitanium is more commonly used in aerospace, medical prosthetics, and marine applications. When Titanium meets the technical requirements, it is a very cost-effective metal, making it a preferred choice over Zirconium.

Application of Zirconium

Zirconium is highly suitable for various markets due to its unique properties. It is estimated that approximately 90 percent of Zirconium production is intended for nuclear reactor technology. In addition, Zirconium is used in various other applications such as:

- Chemical industry

- Medical devices

- Aerospace

- Hydrogen storage

- Military industry

Zirconium in nuclear reactors: Zircaloy

Zirconium is essential in generating nuclear energy. Three notable properties make the metal particularly suitable for use in nuclear reactors: Z irconium is highly heat-resistant, absorbs very few neutrons, and is very corrosion-resistant up to a temperature of 750°C.

“Heat exchanger shell and tube repairing in factories of petrochemical industrial”

Generating nuclear energy is a process in which heat and neutrons are crucial. Zirconium can handle both well, as its melting point is 1855°C and it absorbs few neutrons. The free movement of neutrons is essential in splitting Uranium atoms, and because the metal absorbs so few neutrons, neutrons can move efficiently, enabling nuclear energy to be generated efficiently.

In addition, Zirconium is essential in safely stopping the nuclear reaction. To stop the nuclear reaction, fuel rods that absorb neutrons are activated. These rods are cooled with cooling water. The warm metal surface of the rods must not react with the cooling water, as this would result in the highly explosive hydrogen. Therefore, the rods are equipped with a Zircaloy sheath. Zircaloy is an alloy, available in various compositions, that consists of at least 97 percent (95% for nuclear applications) Zirconium. In addition, the alloy contains a small amount of Tin, Iron, Nickel, Chromium, or Niobium.

Zirconium in chemical processes

Zirconium is widely used in chemical processes, both in the production of catalysts and pigments, as well as for the protection of equipment likestorage tanks, pipelines, etc. Zirconium and its various alloys provide the corrosion and heat resistance necessary for safe and efficient chemical processes involving acids, bases, and other corrosive substances and/or high temperatures.

Interested in the benefits of working with Metel? Our team would be happy to tell you everything about our program or approach and share examples of successful collaborations with customers in your specific market. Make an appointment via 0416 – 724 800 or email n.kesteloo@metel.nl.