NEW COMPANY FACILITY SUPPORTS FURTHER GROWTH OF METEL

Metel has experienced significant growth in recent years, and its ambitions remain high. Therefore, it was time to acquire a new company facility with more space for the storage of special metals and new colleagues. Director Dennis Wijnants shares insights into the construction of their new company facility, which they moved into in May of this year, and outlines Metel’s ambitions for 2024.

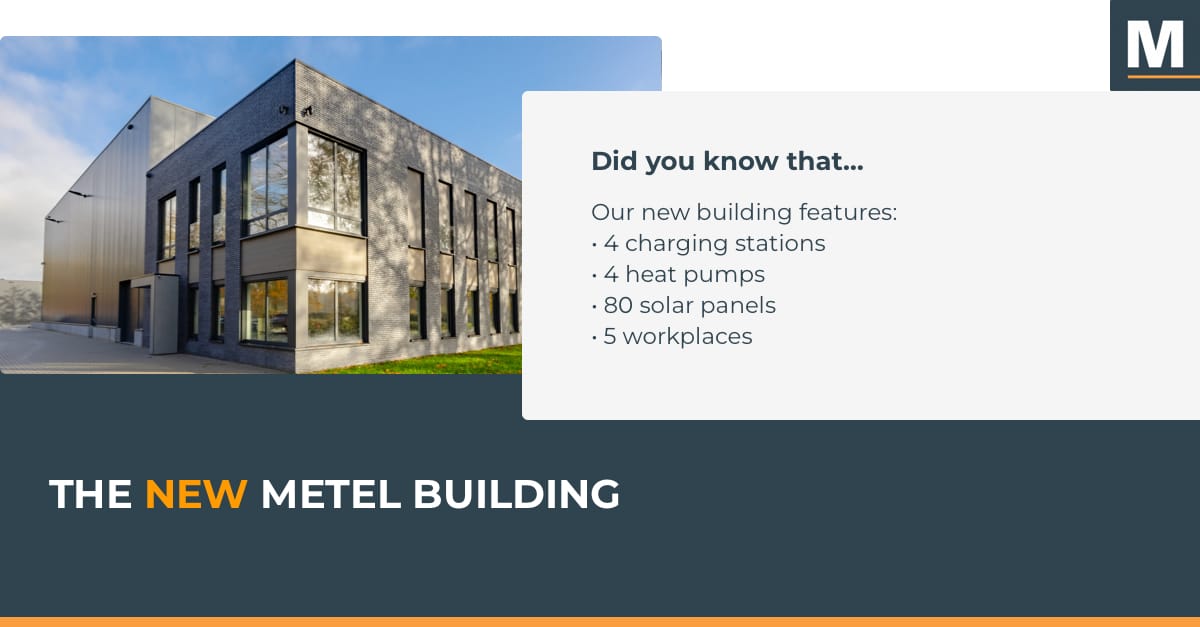

Director Dennis Wijnants proudly discusses Metel’s new company facility, saying, “Everything is new and fresh, we have more space, and the facility is climate-neutral.” The construction and relocation took some time, but since May of this year, the team has been operating from the new facility in Drunen.

“We initially looked at land in Waalwijk, where we were previously located. However, only large plots of land were available there, suitable for constructing a new distribution center the size of Bol.com, for example. In March 2021, we started working on the Drunen property, which took some time, and then, of course, construction had to follow. We are still working on a few finishing touches, such as an electric access gate and motion sensors, but it’s already a great working environment here.”

SUSTAINABLE AND COMFORTABLE

Thanks to 80 solar panels and 4 heat pumps, the new facility is climate-neutral. It is also much better insulated than the previous one and features a heat recovery system: heat generated by the underfloor heating rises and is redirected back down by the system, creating efficient heat circulation.

Another advantage of the new facility is the space, designed to accommodate the team’s growth and Metel’s services. In addition to Dennis’s office, the open-plan office space has four workstations, there is a meeting room with six seats, and a comfortable kitchen, making it possible to enjoy soup and fried eggs for lunch. “We will soon welcome a new colleague in the back office, and next year, we hope to expand our team with one more person, for which we now have sufficient space.”

The office has become a pleasant workspace, partly due to additional measures taken to improve acoustics. “We have concrete walls, glass partition walls, and a poured floor. The construction plan already included a suspended ceiling to dampen the sound between all these hard materials. However, that proved insufficient. Now, all spaces are equipped with acoustic panels, fabric furniture, high-pile carpets, plants, and wooden artworks aimed at enhancing acoustics for a comfortable working environment.

GROWTH AND METEL’S AMBITIONS IN SPECIAL METAL SUPPLY

The growth and ambition of Metel were significant reasons for the relocation. “Metel started as a subsidiary of the company with which we shared a facility in Waalwijk. However, that arrangement ended several years ago. Meanwhile, both organizations continued to grow, and we began to get in each other’s way mainly in the warehouse. As a result, part of our stock was kept by our transporter, but that was not ideal. With the new facility, we deliberately focused on having a large warehouse, aligning with our ambitions for the coming years.”

The new warehouse is 10 meters high and features roller doors that are 7 meters wide, allowing even the largest products that Metel supplies, such as 6.2-meter-long titanium tubes, to easily move in and out of the warehouse. The floor is specially designed to support a substantial tonnage, making the facility suitable for the special metals stored by Metel. The result is a warehouse ready for the future.

AMBITION: GROWTH IN SPECIAL METAL SUPPLY AND NEW ISO CERTIFICATION

What does the future hold for Metel? “We have experienced significant growth in recent years, and we want to continue that growth. In the coming year, our focus lies in Titanium and obtaining our ISO AS9120 certification.”

Metel has recently expanded its collaboration with its Titanium factory. “We have the exclusive consignment rights for Europe from this factory. This allows us to keep more Titanium products in stock and serve the European market much faster from the Netherlands. The delay caused by transport from our factory is eliminated, improving our delivery times from sometimes several weeks to one or two days.”

Additionally, 2024 is marked for obtaining the ISO AS9120 certification, allowing Metel to directly supply the aviation industry. “Currently, we can only supply indirectly because the factories we collaborate with are certified, but we are not yet. However, we aim to enhance our service and direct delivery with the appropriate certification is part of that.”

TEAM EXPANSION

The ambitions and expectations are high, and a strong team is essential. Therefore, Marc will soon join Metel as a new back-office employee. He will focus on tasks such as requests to factories and proper registration in the CRM system, allowing Manager Nick Kesteloo to concentrate on customer contact, and Dennis to focus on entrepreneurship and handling complex requests.

Dennis will also take on the role of trainer to gradually educate new colleagues about the special metals that Metel supplies. “We train new employees ourselves because the metals we supply are so specialized that standard metal courses or training programs do not fully match our needs. We start with general knowledge of Titanium and gradually expand that with other metals.” When asked where Dennis acquired this knowledge, he says, “I learned the basics from a metallurgist when I was still an employee. In addition, I have read books from the Metallurgy program, searched for a lot of information, and acquired knowledge through the factories we work with.”

Next year, Dennis hopes to expand the team with one more colleague, but for now, the focus is on training Marc. If you are interested in vacancies at Metel, keep an eye on the website or LinkedIn page. For inquiries, please contact them via info@metel.nl or +31 (0) 416 724 800.